1. Main advantages

Everyone knows that 45# steel is high carbon steel and is widely used in the field of auto parts, but its machined parts are very easy to rust, especially in high temperature and high humidity weather, because carbon steel is easy to form a primary battery (Fe is the anode and C is the cathode), so it is easily corroded.

Therefore, a water-soluble fully synthetic cutting fluid was specially developed for the parts used in the automotive industry (material 45# steel) and aluminum alloys that are prone to rust after machining. The integrated functions of cutting, cleaning, rust removal and rust prevention are All-in-one formula---(cutting + cleaning + rust removal + rust prevention) four in one.

HF-MW-09 cutting fluid has comprehensive features that are not available in the current market cutting fluid:

1. It has the characteristics that cutting fluid should have—excellent lubricity, wettability, cooling, dispersibility, extreme pressure bearing capacity.

2. Efficient cleaning ability----Excellent cleaning ability, the machined parts can be exempted from the requirements of subsequent cleaning.

3. Efficient continuous corrosion inhibition and strong rust removal. The rust removal principle is not the usual acid-base rust removal but the complexation principle, because the complex rust removal will not occur the usual rust rebound. Therefore, it can be used as both a rust remover and a rust inhibitor.

4. Reduce costs visibly to the naked eye --- In terms of materials, only one cutting fluid can effectively replace four materials (cutting fluid + cleaning agent + rust remover + rust inhibitor); in terms of working hours, it has more advantages The extremely high cost performance also greatly reduces the trouble and cost caused by rework. At the same time, production management has been fully optimized.

2. Main application 2.1. Suitable for machining of hard materials such as stainless steel, aviation aluminum, aluminum alloy, wafer, chip, semiconductor, copper, and other non-ferrous metals

2.2. The recommended concentration is 6%---10%; the comprehensive effect of cutting and other working fluid prepared with deionized water is better

2.3. Shelf life: 2 years (original packaging)

3. Main performance

Fully synthetic water-soluble metal cutting fluid

With: lubrication + cleaning + rust removal + rust prevention, four-in-one function

3.1. Specific gravity (20℃, g/cm3): 1.1-1.3

3.2. Surface tension 28.5mN/m

3.3. Cloud Point: None

3.4. Metal content such as potassium, iron and copper <10ppm

3.5. Content of non-metals such as sulfur and halogen

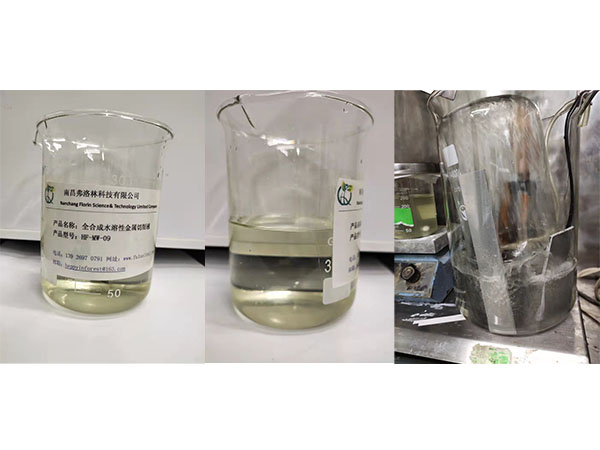

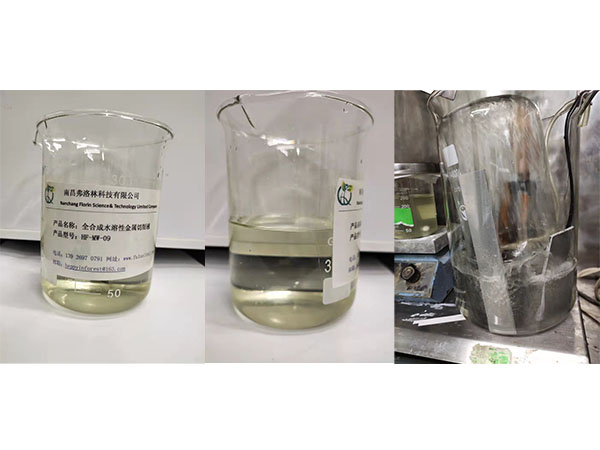

The picture demonstration is as follows

1. Carbon steel (45# steel), only the effect before and after spraying/soaking

2. Aluminum alloy, only the surface effect before and after spraying/immersion

III. Surface changes of 45# carbon steel and aluminum alloy under spray/immersion conditions of metal cutting fluid - both rust layer and aluminum alloy surface oxide layer pass through The oxide layer is removed by complexation reaction. At the same time, unlike the conventional acid-base rust removal principle, the problem of "re-corrosion" will occur.