First, the main features:

It has excellent lubricity, wettability, cooling, dispersibility and extreme pressure bearing capacity, thereby greatly reducing cutting resistance and stress, reducing surface defects, and preventing frequent changes in chip processing dimensions due to temperature differences.

Efficient and sustained corrosion inhibition and rancidity resistance;

pH neutral, no irritating odor, safe and environmentally friendly;

Very low foam, easy to clean, no asphalt slag formation;

No sulfur/phosphorus/halogen/phenol/nitrite/mineral oil/animal oil, etc.;

Does not contain anions and cations, and does not produce negative effects such as ion pollution;

Excellent stability of product quality and performance from batch to batch.

Second, the main purpose:

It is mainly a fully synthetic water-soluble cutting fluid specially developed for wafer dicing to meet the harsh requirements of wafer dicing and subsequent processing.

The recommended concentration is 6%---10% (volume ratio); it is required to use deionized water to prepare the working solution.

Three, the main physical and chemical properties:

Appearance: Homogeneous light yellow transparent liquid;

pH value: 8.5±0.5;

Friction coefficient: 0.0616 (785N, 1200 rpm, 120 seconds);

Specific gravity (20℃, g/cm3): 1.06;

Viscosity (mm2/s, 40℃): 14.36;

Surface tension: 28.6mN/m;

Extreme pressure data: Pb value: 1569N Pd value: 1961N;

Metal ion content: sodium, potassium, iron and copper content: ≤10ppm;

Anion: halogen (in chlorine) content: ≤10ppm;

Water solubility: completely miscible with water;

Four. Packaging:

Use specialized chemical HDPE plastic barrels and never use iron barrels or galvanized barrels to avoid ionic contamination of wafers.

200kg and 25kg;

Five, matters needing attention:

Incompatible with strong oxidizing agents and strong bases.

Six: Storage and Shipping:

Because this cutting fluid is non-toxic, non-irritating and non-flammable, it can be transported and stored as common chemicals.

Store in a cool, dry and ventilated room, sealed and sealed after each opening;

Avoid strong oxidants, acids, high temperature environments, direct sunlight, rain, etc., and keep away from fire sources.

VII. Validity period:

It is valid for two years in original packaging.

VIII. Delivery time:

15 working days after receiving the order.

IX. ROHS report

十、Wafer cutting fluid TDS test report

十、Wafer cutting fluid TDS test report

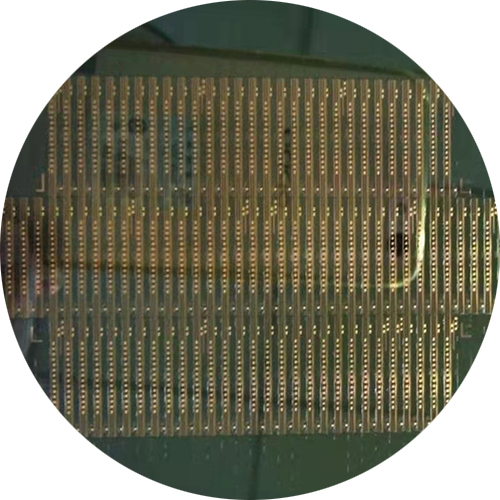

十一、wafer cutting

十一、wafer cutting

十、Wafer cutting fluid TDS test report

十、Wafer cutting fluid TDS test report

十一、wafer cutting

十一、wafer cutting